Picking process in DAX 2009

Picking process in Dynamics AX 2009

There are three ways in which picking can be done in Dynamics AX 2009.

1. Direct pick posting from Item (stock) button from the order/journal lines

2. Posting 'Picking list' from order header.

3. Using the advanced warehouse management (Warehouse II) creating output orders, shipment, picking route and/or pallet transports.

Note - If the inventory model group (or stock model group in UK English) of the item is set as 'Picking requirements' checked; then physical posting on transaction cannot be done until picking is done. This parameter can be found in Inventory management / Setup / Item model groups / Setup tab / Physical update field group. The item model group is attached to each item (mandatory field) in General tab in item's master form.

Let's discuss these options in detail.

Direct pick posting

This posting is available in each form where outgoing item transaction is made e.g. sales order, transfer order, inventory journals. From the line section of the form, click 'Item' button choose 'Pick'. In the 'Pick' form, you will see the transactions in the upper grid, which shows the item transactions in the corresponding order/journal. You can mark 'Auto create' check box for the line to automatically create a line in 'Pick now' grid for whole quantity for that line. Alternatively, you can select the bottom grid and then create a new record, mention the dimensions and enter the quantity you want to pick. Save the record. Click 'Post all' button on the lower half section of the form. This will pick post the lines chosen.

Picking list posting

Picking list posting can be used as an alternative way to post picking in the system. You will be able to post the picking from the header level instead of individual line level. However, you will still have the flexibility to add/delete items and/or quantities to pick at the time of posting. This is two step process of picking.

Firstly a 'Picking list' posting is done. This is typically done by warehouse manager to generate (post / print) the picking list for the order. Once the picking list is posted, the output orders are generated and added to the shipment.

Secondly, a 'Picking list registration' is posted. This is generally done by warehouse employee saying that he/she have picked the actual items from the location/dimension mentioned in the picking list.

The first posting is done by clicking the 'Posting /Picking list' button in the posting section of the order header. Second posting is done by clicking the 'Posting / Picking list registration' button in the order header. The picking list registration form shows the picking route for the line. The lines can be selected from second grid and then posting can be done from 'Updates / Update selected' button on header. This will pick post the line.

If the picking route needs to be dealt at more granular level, the pick route can be started by clicking 'Functions / Start picking route' button . This is discussed in third way of posting picking.

Picking using advanced warehouse management

Advanced warehouse management (Warehouse II) in Dynamics AX 2009, provides many more option to control picking and shipping process. Lets look at the few setups which will help system work correctly.

Setup

Item setup - Item details / Setup tab / Warehouse management field group - Fields in this group defines the basic defaults for the warehouse management handling of the item. Most of these are self explanatory and related to creation of pallet transport. 'Package handling time' is used to calculate the time required for handling items while creating picking routes. In the same tab 'Volume' can be defined under 'Item data' field group. This will help make the picking route based upon total volume of the items.

Store area - Inventory management / Setup / Inventory breakdown / Store area - If a store area is a picking area then the automatic refill transport and mode of handling the picking list can be defined. Checking automatic refill transport will create a refill transport (a type of pallet transport) in case enough quantity in unavailable at location for picking. Mode of handling defines if the item will be continuously updated (on line; e.g. handheld device) or updated in once (print, mark and then update in system).

Inventory model group - Inventory management / Setup / Inventory / Inventory model group / Setup tab / Warehouse management field group / Consolidated picking check box. Mark this check box to use the consolidated picking functionality via shipments.

Warehouse - Inventory management / Setup / Inventory breakdown / Warehouses - On the 'Warehouse management' tab define 'Picking route time' - Total time for a picking route, 'Picking route volume' - Maximum volume for a picking route and 'Picking route transit time' - Time takes to pick one line from the pick route. These fields will play important role when system creates picking routes.

Location - Inventory management / Setup / Inventory breakdown / Locations - Under 'General' tab, in 'Location' field group, define Picking area.

The above list may not be complete but it will give you a hint which areas to look at to get correct result from the system.

Procedure

From the order/journal line level, click on the Inventory / Output order button. If the output order already exist for the line, it will open its form showing the order details. Otherwise, it will open a small dialog with the editable number quantity for which output order needs to be created. Click OK in the dialog to create the output order.

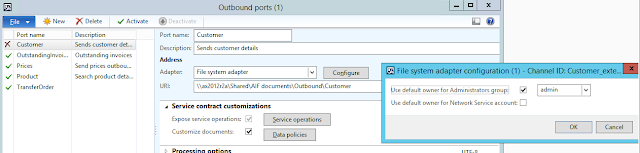

Now these output orders can be made part of different shipment, based upon how you want to ship these orders out. According to your setup, the output orders will automatically attached to a shipment already existed (or by creating a new one) for the customer/order/site/warehouse. But before activating the shipment, user have all the time to remove the output orders from one shipment to other.

Note- The same results can also be obtained by 'Picking list' posting from the order header level.

Go to Shipments form from Inventory management / Common forms. In this form click on the 'Show lines' button to view/add/delete the lines from the shipment. If you delete a line(output order) from shipment, it will still be available to be picked up for other shipments manually. The shipments can also be manually created as required. Next step is to activate the shipment. This can be done by 'Functions / Activate' button. There are other intermediate steps as well i.e. 'Reserve now', 'Activate picking' and 'Activate pallet transport'. 'Activate' button include all these steps in one go. It will reserve the items for picking, create the picking routes and create the pallet transports.

Note - Pallet transport will only be created if proper setup is created for it.

The picking route can be started from 'Picking route' form from 'Inventory management / Common forms'. At starting a picking route, it will be assigned to one of the employee (generally a warehouse worked). This employee can then take this forward. He/she can see the picking route in bottom 'Active' tab when he/she opens the 'Picking route' form. The employee should click on the 'Approve details' button to open the 'Approve line' form. Checking the correct dimensions and quantity on the line he/she should click the 'Pick selected' button on the form. This will automatically close the 'Approve line' form the and the picking line will appear in the 'Picked' tab in 'Picking route' form. If all the picking lines are picked then the form will go blank and the picking route will be marked as completed. If all the picking routes associated with the order lines are completed, then the order line will be marked as pick posted.

Summary

Microsoft Dynamics AX 2009, provides different means of achieving the same results in the system. It depends on the business process for the level of granularity you choose for implementation.

This comment has been removed by the author.

ReplyDeleteNice and interesting information and informative too. pallet transport from sydney to perth

ReplyDeleteThank You for sharing such a wonderful blog with us. It is very useful to me. To get more information about pallet transport sydney to brisbane

ReplyDelete